Poor Inventory Management Examples Made by Huge Brands

As many retailers can attest, poor inventory management can seriously harm a company and its brand/brands, leading to short-term financial damage, a fall in stock prices, bankruptcy, or company closure.

From small businesses to companies with large inventories, there's always a concern with the everyday and long-term challenges of inventory management. Some companies may look at updating legacy management systems, while others look for real-time ways to future-proof the business. High-profile, well-known, and loved brands are not exempt from inventory control problems, and many retailers can learn valuable lessons from their mistakes.

How Poor Inventory Management Can Kill a Brand

When supply chain and inventory problems arise, retailers face some consequences. Here are some poor inventory management examples:

1) Using outdated methods to track items , such as:

- Manual inventory tracking , which becomes time-consuming and error-prone as your company grows. You’ll always be one step behind your actual inventory levels, which will cause ordering issues.

- Excel/electronic spreadsheets , which are prone to severe errors. In a study of errors in 25 sample spreadsheets, the Tuck Business School at Dartmouth College found that 15 workbooks contained 117 errors. While 40% of those errors had little impact on the businesses studied, seven errors caused massive losses of $4 million to $110 million, according to the researchers’ estimates.

2) Too large of an inventory . Reports show that most businesses have 20-40% of their working capital tied up in inventory. If you have a greater amount of product than what demand calls for, you won't be able to fulfill orders optimally. Large stock levels don’t just lead to more management headaches; they can also cut into profits and cause dead stock.

3) Inadequate reports and demand forecasting . When companies don’t use or have access to accurate information such as sales trends, best-selling products, customer behavior, and the like – they fall into the trap of ordering too much inventory. When this happens, companies experience the problems of an excessive amount of finished goods, ordering too few finished products, experiencing shortages, and losing customers. With accurate real-time reporting accessible 24/7, anytime, from anywhere, companies can forecast their customers’ future behavior and order accordingly to meet customer demand without exceeding their budget.

Four Examples of Poor Inventory Management

Let’s take a look at four high-profile brands and how a crisis of inventory created some real problems that companies could have prevented had they managed their inventory properly:

Nike’s Excess Inventory Problem

As one of the world's most recognized athletic brands, Nike has many goods to manage. And as a result, it has had difficulty keeping inventory under control. In the early 2000s, the company adopted an updated inventory management software after losing around $100 million in sales due to issues with tracking goods. The software promised to help Nike predict items that would sell best and prepare the company to meet demands, but bugs and data errors resulted in incorrect demand forecasts and led to millions more lost.

Nike’s case illustrated just how crucial it is to correctly manage stock levels and your inventory management system. When choosing an inventory management solution, it’s vital to ensure the quality of software your vendor provides is accurate, flexible, and customized for your particular business. It needs to be able to grow and change as the business and the customer base change.

Nike continues to have issues with inventory. 2016 was challenging for the retailer, as Nike's gross margin declined due to a higher percentage of discounted sales because of inventory management problems. The retailer continues to take steps to control its inventory management practices through manufacturing overhauls better and allowing new technology to bring manufacturing to the digital age. Ultimately Nike will remain a global leader as it keeps exploring new markets, innovating new products, and generating its supply channels.

Best Buy’s Christmas Inventory Nightmare

In December 2011—smack dab in the middle of the holiday season— Best Buy issued a statement : “Due to the overwhelming demand of hot product offerings on BestBuy.com during the November and December period, we have encountered a situation that has affected redemption of some of our customers’ online orders. We are very sorry for the inconvenience this has caused, and we have notified the affected customers.”

Customers were infuriated by Best Buy’s decision to cancel orders instead of delaying shipment, which was most likely because the company ran out of stock. Reportedly Best Buy sold many of the withdrawn items on Black Friday. The retailer essentially cast a wide net, collecting as many orders as possible, likely knowing it would be unable to fulfill them all.

As Best Buy proved, buying items online as an alternative to in-store still carries a risk. Consumers don't know for a fact that they will get their product. While receipts are issued and shipping estimates are given, some variables still allow consumers to be 100% certain their purchase will be complete every time. It’s not hard to imagine that Best Buy probably lost many of its customers to Amazon after that 2011 debacle.

Target’s Disastrous Failed Expansion into Canada

Target is a well-loved brand in the US, so it seemed only natural that it would be just as well-received with expansion up north into Canada. Target executives had a decision to make. They needed a way to track their stock levels and chose to work with an entirely new and untested system. Target Canada would eventually learn what happens when inexperienced employees working under a tight timeline are expected to launch a retailer using technology that nobody—not even at the US headquarters—understood.

In 2013, the company had trouble moving products from its large distribution centers onto store shelves, leaving Target outlets poorly stocked. It didn’t take long for Target to figure out the underlying cause of the breakdown: The data contained within the company’s supply chain software, which governs the movement of inventory, was riddled with flaws. The checkout system was glitchy and didn’t process transactions properly. Worse, the technology managing inventory and sales were new to the organization; no one seemed to fully understand how it worked.

Why Too Much Inventory is Bad

Besides technology issues, problems of ordering and inventory were running amok. Target stalled items with long lead times coming from overseas—products weren’t fitting into shipping containers as expected, or tariff codes were missing or incomplete. Finished goods that made it to a distribution center couldn’t fulfill orders for shipping to a store. Other items weren’t able to fit correctly onto store shelves. What appeared to be isolated fires quickly became a raging inferno threatening to destroy the company’s supply chain.

Target’s distribution centers were bursting with products and dead stock. Target Canada had ordered way more stock than it could sell. The company had purchased a sophisticated forecasting and replenishment system, but it wasn’t beneficial at the outset, requiring years of historical data to provide meaningful sales forecasts. When the buying team was preparing for store openings, it relied on wildly optimistic projections developed at US headquarters.

Roughly two years after they launched, Target Canada filed for creditor protection, marking the end of its first international foray and one of the most confounding sagas in Canadian corporate history. The debacle cost the parent company billions of dollars, sullied its reputation, and put roughly 17,600 people out of work.

Supply Chain Disruption Closed 900 KFC Branches in the UK

In February 2018, Kentucky Fried Chicken (KFC) was forced to close many of its 900 UK branches due to supply chain disruption . In a press release, the fast-food giant stated, “We've brought a new delivery partner onboard, but they've had a couple of teething problems - getting a fresh chicken out to 900 restaurants across the country is pretty complex!”

By changing their delivery partner, approximately 750 KFC outlets across the UK faced delays in receiving their daily delivery of fresh chicken, meaning their restaurants could not supply customers and ultimately had to close. At the time, many thought the giant could lose up to £ 1 million daily.

Could KFC have done more to ensure their supplier was suitable for the job? The thought is that multiple supplier contracts could have spread KFC could have avoided the weight of the mammoth delivery task and a crisis like this. Another issue was that their supplier only had one distribution spot instead of multiple, which would have been able to service the outlets much more manageable.

What Can Businesses Learn From Inventory Management Problems?

It takes more than having a large inventory of products to keep a retail business running. All that inventory must be stored, moved, and in the right place at the right time. Warehouses need to be efficient, and their tools and workhorse vehicles are kept up to date. Every part of the supply chain needs to coordinate, from obtaining raw materials to distributing finished goods.

The same can be said about the technology to track and manage the inventory as it moves locations. Companies need to know accurate numbers when it comes to inventory. Their livelihood, franchisees, investors, and employees depend on it! When you don’t see what you have or how/when it moves about, there’s no actual knowledge about the most critical aspect of your business – your inventory.

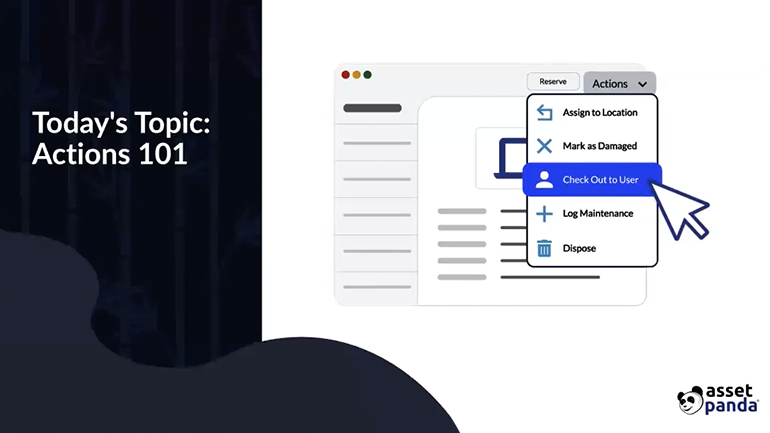

Retailers of all sizes are looking for easy-to-use, mobile, affordable, secure, and rapidly deployable asset tracking systems . They need a reliable method to track the thousands of inventory items that move through their location(s)/warehouses daily. Asset Panda is the answer. We leverage the cloud and free mobile apps to help retailers get the information they need about their inventory. Our retail and small business clients know where their inventory is, who has what, and its condition.

Asset Panda's Inventory Management System

Asset Panda is simple to use with a very intuitive platform. Our system records the entire lifecycle of an asset. Other capabilities include custom reports, depreciation calculation, mobile enterprise service desk, and more. Leading retailers recognize that better inventory tracking processes will lower business costs by reducing loss, property taxes, and the amount of insurance they must carry. All the home offices must run reports to get detailed, real-time data from the field.

Try our inventory management software free for 14 days so you can see what’s truly possible when you manage your inventory the right way! (No credit card required).

Related News & Press

Ep 4. Actions 101

Watch Asset Panda in our 4th product updates webinar to watch us d...

The Importance of IT Inventory Audits

An effective IT asset management plan should include routine IT in...

IT Asset Management Best Practices

Let’s take a look at what IT asset management is, how it benefit...

Learn more from an Asset Panda expert

Get a FREE consultation with an asset tracking expert to find out how you can transform your asset tracking.

Contact our Sales Team at (888) 928-6112

Get a Demo

MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study: Inventory Management Practices at Walmart

Case Study: Inventory Management Practices at Walmart

About walmart.

Wal-Mart Stores, Inc. is the largest retailer in the world, the world’s second-largest company and the nation’s largest nongovernmental employer. Wal-Mart Stores, Inc. operates retail stores in various retailing formats in all 50 states in the United States. The Company’s mass merchandising operations serve its customers primarily through the operation of three segments. The Wal-Mart Stores segment includes its discount stores, Supercenters, and Neighborhood Markets in the United States. The Sam’s club segment includes the warehouse membership clubs in the United States. The Company’s subsidiary, McLane Company, Inc. provides products and distribution services to retail industry and institutional foodservice customers. Wal-Mart serves customers and members more than 200 million times per week at more than 8,416 retail units under 53 different banners in 15 countries. With fiscal year 2010 sales of $405 billion, Wal-Mart employs more than 2.1 million associates worldwide. Nearly 75% of its stores are in the United States (“Wal-Mart International Operations”, 2004), but Wal-Mart is expanding internationally. The Group is engaged in the operations of retail stores located in all 50 states of the United States, Argentina, Brazil, Canada, Japan, Puerto Rico and the United Kingdom, Central America, Chile, Mexico,India and China.

Walmart Inventory Management

Wal-Mart had developed an ability to cater to the individual needs of its stores. Stores could choose from a number of delivery plans. For instance, there was an accelerated delivery system by which stores located within a certain distance of a geographical center could receive replenishment within a day. Wal-Mart invested heavily in IT and communications systems to effectively track sales and merchandise inventories in stores across the country. With the rapid expansion of Wal-Mart stores in the US, it was essential to have a good communication system. Hence, Wal-Mart set up its own satellite communication system in 1983. Explaining the benefits of the system Walton said, “I can walk in the satellite room, where our technicians sit in front of the computer screens talking on the phone to any stores that might be having a problem with the system, and just looking over their shoulders for a minute or two will tell me a lot about how a particular day is going. On the screen, I can see the total of the day’s bank credit sales adding up as they occur. If we have something really important or urgent to communicate to the stores and distribution centers, I, or any other Wal-Mart executive can walk back to our TV studio and get on that satellite transmission and get it right out there. I can also go every Saturday morning around three, look over these printouts and know precisely what kind of work we have had.”

Wal-Mart was able to reduce unproductive inventory by allowing stores to manage their own stocks, reducing pack sizes across many product categories, and timely price markdowns. Instead of cutting inventory across the board, Wal-Mart made full use of its IT capabilities to make more inventories available in the case of items that customers wanted most, while reducing the overall inventory levels. Wal-Mart also networked its suppliers through computers. The company entered into collaboration with P&G for maintaining the inventory in its stores and built an automated reordering system, which linked all computers between P&G and its stores and other distribution centers. The computer system at Wal-Mart stores identified an item which was low in stock and sent a signal to P&G. The system then sent a re-supply order to the nearest P&G factory through a satellite communication system. P&G then delivered the item either to the Wal-Mart distribution center or directly to the concerned stores. This collaboration between Wal-Mart and P&G was a win-win proposition for both because Wal-Mart could monitor its stock levels in the stores constantly and also identify the items that were moving fast. P&G could also lower its costs and pass on some of the savings to Wal-Mart due to better coordination.

Employees at the stores had the ‘Magic Wand,’ a hand-held computer which was linked to in-store terminals through a radio frequency network. These helped them to keep track of the inventory in stores, deliveries and backup merchandise in stock at the distribution centers. The order management and store replenishment of goods were entirely executed with the help of computers through the Point-of-Sales (POS) system. Through this system, it was possible to monitor and track the sales and merchandise stock levels on the store shelves. Wal-Mart also made use of the sophisticated algorithm system which enabled it to forecast the exact quantities of each item to be delivered, based on the inventories in each store. Since the data was accurate, even bulk items could be broken and supplied to the stores. Wal-Mart also used a centralized inventory data system using which the personnel at the stores could find out the level of inventories and the location of each product at any given time. It also showed whether a product was being loaded in the distribution center or was in transit on a truck. Once the goods were unloaded at the store, the store was furnished with full stocks of inventories of a particular item and the inventory data system was immediately updated.

Wal-Mart also made use of bar coding and radio frequency technology to manage its inventories. Using bar codes and fixed optical readers, the goods could be directed to the appropriate dock, from where they were loaded on to the trucks for shipment. Bar coding devices enabled efficient picking, receiving and proper inventory control of the appropriate goods. It also enabled easy order packing and physical counting of the inventories. In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor the sales of their goods at stores and replenish inventories. The details of daily transactions, which approximately amounted to more than 10 million per day, were processed through this integrated system and were furnished to every Wal-Mart store by 4 a.m., the next day. In October 2001, Wal-Mart tied-up with Atlas Commerce for upgrading the system through the Internet enabled technologies. Wal-Mart owned the largest and most sophisticated computer system in the private sector. The company used Massively Parallel Processor (MPP) computer system to track the movement of goods and stock levels. All information related to sales and inventories was passed on through an advanced satellite communication system. To provide back-up in case of a major breakdown or service interruption, the company had an extensive contingency plan. By making effective use of computers in all its company’s operations, Wal-Mart was successful in providing uninterrupted service to its customers, suppliers, stockholders and trading partners.

Related posts:

- Case Study: Supply Chain Management of Walmart

- Case Study: How Walmart Enhances Supply Chain Management with ERP Initiatives?

- Case Study: Why Walmart Failed in Germany?

- Inventory Management Practices in Multinational Corporations

- Case Study of Walmart: Procurement and Distribution

- Case Study: Analysis of Performance Management at British Petroleum

- Case Study: Quality Management System at Coca Cola Company

- Case Study of Burger King: Achieving Competitive Advantage through Quality Management

- Inventory Management Concepts in Supply Chain Management

- Inventory Management

One thought on “ Case Study: Inventory Management Practices at Walmart ”

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Download Free PDF

Inventory Management-A Case Study

As a result to today's uncertain economy, companies are searching for alternative ways to stay competitive. This study goes through the process of analyzing the company's current forecasting model and recommending an inventory control model to help them solve their current issue. As a result, an Economic Order Quantity (EOQ) and a Reorder Point was recommended to help them reduce their product stock outs. The shortage of raw material for production always makes the process discontinuous and reduces the productivity. The ABC analysis technique for the inventory control system is first used to identify the most important multiple products and then the economic order quantity (EOQ) of each product is developed to find their inventory model equation individually.

Related papers

Company X is a small manufacturer in Thailand that produces hundreds of small joint hinges or lockers for the home furniture around the world. The company usually orders mass different raw material irregularly and causes different raw material inventory shortage for the multiple products manufacturing process. The shortage of raw material for production always makes the process discontinuous and reduces the productivity. To solve this problem, this paper intends to study a raw material inventory control model for the most important multiple products production in the company X. The ABC analysis technique for the inventory control system is first used to identify the most important multiple products and then the economic order quantity (EOQ) of each product is developed to find their inventory model equation individually. Using the regression technique, the raw material inventory control model for the important multiple products is constructed. The result of regression model analysis shows a goodness of fitting to the selected important multiple products and would expected to avoid the raw material shortage problem and help to organize the complicate inventory control system for company X in the future.

International Journal for Research in Applied Science and Engineering Technology, 2018

In today's global market, companies are looking for growth and opportunities to reduce their total cost and management of companies would like to increase quality, efficiency and capability without increasing their investment. The success of many businesses is related to their ability to provide goods and services at right time and in right place. Different organization adopt different inventory control methods to manage their inventory to avoid stock-out and overstock. In this paper a case study of a company in Vasai, Maharashtra is considered. For this study the EOQ (Economic Order Quantity) technique of inventory management is considered. In this company inventory management is not proper which causes overstock and sometimes stock-out. In this paper inventory management technique is considered and costs are calculated to compare two methods, one is used by this company and other is recommended model.

Today, the effective inventory management plays an im-portant role in the success of the organizations in the new business environment. It is not clearly possible for the organizations that store hundreds of inventory items to economically design an inventory management policy for each inventory item separately. Moreover, various inven-tory items may play quite different roles in the business of the organization. Hence, the managers need to classify these items in order to control each inventory category properly based on its importance rating. This research is composed of the following sections: In the first section, the criteria affecting the evaluation of the inventory control system of the studied factory and the priority of each one of them will be identified, in the second section, the prior-ity of each criterion in each inventory category (A, B, C) is calculated using the analytical hierarchy process, in the third section, a mathematical model will be presented to evaluate th...

IAEME PUBLICATION, 2020

The success of many businesses is related to their ability to provide goods and services at right quality, quantity and at the right location. Based on this premise, this study examines inventory management practices in Covenant Bakery and their effects on economic performance. The study aims at determining the degree of importance of each of the inventory items and EOQ for the inventory items. The ABC analysis and EOQ technique were adopted for this study. Amongst others, the study also found that for the organization to minimize total cost Covenant Bakery economic order quanity to be purchased for flour, sugar and butter are 206, 38, and 21 bags respectively per order. Therefore, study recommmends that the organization should maintain tight control over category flour, suagar and butter and loose control for the rest of the inventory items.

Inherent uncertainties in demands and supply make it difficult for supply chains to achieve optimum inventory replenishment, resulting in loss of sales or keeping excessive inventories. An unkempt inventory can take up to one-third of an organization's annual investment. Therefore, in order to compete with invariably erratic demands, it is not only challenging to develop an intelligent system to maintain and control an optimum level of inventory but has also become mandatory. Here we have tried to study the supply chain logistic management in manufacturing industry using XYZ analysis method. Supply chain: Supply chain management (SCM) is the oversight of materials, information, and finances as they move in a process from supplier to manufacturer to wholesaler to retailer to consumer. Supply chain management involves coordinating and integrating these flows both within and among companies Logistic: Logistics management is that part of the supply chain that plans, implements, and ...

The management of supply chain and the role and responsibilities of various persons involved varies from industry to industry. Due to which supply chain management has become a vital issue for manufacturing organizations, professionals and researchers. The ultimate aim of supply chain management is to satisfy the customer at optimum cost. Due to globalization, liberalization and advancement in new technologies supply chain has become more complex, more global and a more critical business function than ever before. In this work EOQ is determined by the junction of Ordering Cost curve and carrying Cost line. This work is a case study in optimal inventory control, applied to B Brown Medical India Pvt. Ltd. This company manufactures IV sets and sutures, right heart catheters, and chip products

The success parameters for any company are on time completion, within specific budget and with requisite performance. In particular an efficient and effective inventory management helps a firm maintaining competitive advantage, especially in a time of accelerating globalization. From this point of view several organizations employ the ABC analysis to have an efficient control on a large number of inventory items. With the increasing levels of integration in manufacturing and service systems conventional ABC analysis is limited because it accounts for only one criterion, mostly "annual dollar usage", for classifying inventory items. To alleviate this shortcoming, this paper proposes a modified version of ABC analysis and Cross Analysis based on Analytic Network Process, a multicriteria approach, that allows to consider several criteria all at once for the optimal choice of materials management.

International Journal of Engineering Research and Technology (IJERT), 2014

https://www.ijert.org/a-decision-model-for-production-inventory-management-in-a-manufacturing-firm https://www.ijert.org/research/a-decision-model-for-production-inventory-management-in-a-manufacturing-firm-IJERTV3IS050847.pdf This paper presents a working inventory model to incorporate the partial back ordering inventory with references to the back ordering inventory model. The reorder point models of maximum expected cost and service level approach were established. Data, covering the demand, setup cost, and the holding cost were obtained from the Champion Breweries Plc, other related data were estimated. These enabled the application of the models to obtain, the review period, (T) the fill rate (F), the stock-out (S) and finally the order quantity (Q). It was found and could be recommended that quantity (Q) of 285022 tons of plan sorghum be placed bi-ennialy with a lead time of four (4) weeks. At a time the stock level is expected to be at 58.746 ton.

Atlantis Highlights in Engineering, 2021

Inventory management is one of the crucial aspects of any business that affects how the company handles the profits and losses. The type of inventory that the management has implemented will either cause problems to the entire supply chain or affect how the overall gains are shared. Through the adoption of inventory controlling technologies, the business will be able to handle the increase in demands and have a transparent, informational infrastructure on the product consumption patterns. One such useful inventory control technology is the Economic Order Quantity (EOQ). Through the adoption and implementation of this technology, the business can enhance its inventory management and the way they handle consumption. More so, this method helps collect information from the various aspects of the business, informing the administration's decisions. Through systematic researching, this paper will tell whether with the use of inventory control systems and, more specifically, the use of Economic Order Quantity will help the business make a stride in reducing the cost associated with inventory managements.

American Journal of Applied Mathematics and Statistics, 2014

This paper investigates the application of inventory model in determining stock control in an organization. A multi-product Economic Order Quantity model was used to determine the optimal order times. The result of the analysis revealed that J.O. Adimoha's investment does not have a proper inventory management which leads them to sometimes either over stock or under stock. The combination of orders at different time interval was carefully and constantly updated and verified because reorder points and EOQ may change. In conclusion, it was discovered that reorder points often coincides close together.

Argumentation

Tropical Medicine and Infectious Disease

Journal of Statistical Modelling and Analytics, 2021

Behavioral Ecology, 2019

American Anthropologist, 2024

Psychology and Education: A Multidisciplinary Journal, 2024

Revista on-line de Política e Gestão EducacionaL, 2017

Nephrology Dialysis Transplantation, 2013

Archives of public health = Archives belges de sante publique, 2018

Materials Science and Engineering: B, 2000

Southern African Journal of HIV Medicine, 2012

JURNAL EKONOMI DAN KEBIJAKAN PEMBANGUNAN, 2018

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

How to Improve Inventory Management – 15 Proven Ways with Case Studies

Demand forecasting.

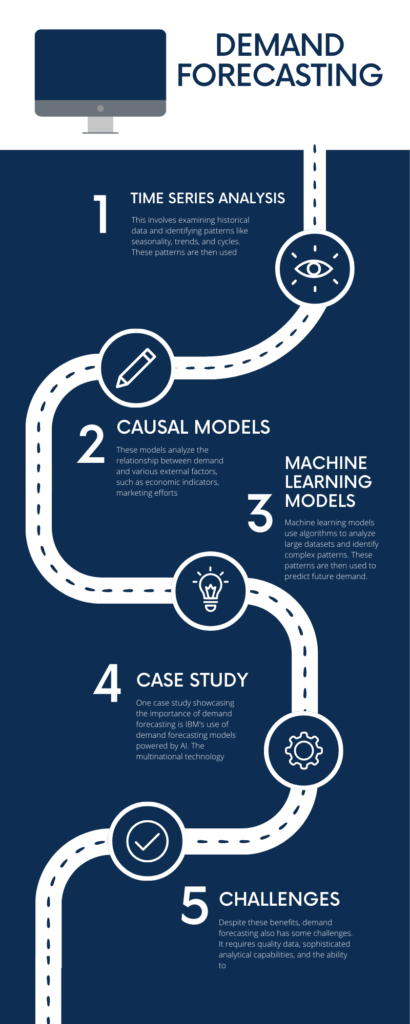

Predicting product demand enables businesses to have the right amount of inventory on hand. Demand forecasting is a key strategy for inventory management as it predicts consumer demand for products or services, allowing businesses to manage inventory more effectively and efficiently.

Demand forecasting uses historical sales data, market research, and statistical methods to predict future demand. The fundamental theories behind demand forecasting include time series analysis, causal models, and machine learning models.

Time Series Analysis

This involves examining historical data and identifying patterns like seasonality, trends, and cycles. These patterns are then used to project future demand.

Causal Models

These models analyze the relationship between demand and various external factors, such as economic indicators, marketing efforts, and price changes.

Machine Learning Models

Machine learning models use algorithms to analyze large datasets and identify complex patterns. These patterns are then used to predict future demand.

One case study showcasing the importance of demand forecasting is IBM’s use of demand forecasting models powered by AI. The multinational technology company has been able to achieve a reduction in forecasting errors by up to 28% through their AI-enabled models.

IBM applied machine learning to time-series forecasting, which allowed them to generate short-term and long-term sales forecasts at scale across various product categories. They used different AI models such as Auto-Regressive Integrated Moving Average (ARIMA), Long Short-Term Memory (LSTM), and Decision Trees to make their predictions.

Furthermore, IBM utilized a combination of structured (e.g., sales numbers, stock levels) and unstructured data (e.g., text reviews, social media sentiment) in their forecasting models. By combining different types of data and using machine learning to process it, IBM could create more accurate and sophisticated demand forecasts.

The accuracy of demand forecasting can have a significant impact on business performance. According to a report by the Global Journal of Management and Business Research, a 1% improvement in forecast accuracy can result in a 2% decrease in inventory costs. Thus, demand forecasting can lead to substantial cost savings and increased profitability for businesses.

Despite these benefits, demand forecasting also has some challenges. It requires quality data, sophisticated analytical capabilities, and the ability to adjust forecasts based on changing market conditions. Therefore, businesses need to invest in technology, data management, and analytics capabilities to leverage demand forecasting effectively.

Safety Stock

Having a safety stock can mitigate the risk of stockouts. Safety stock is a fundamental inventory management strategy where companies keep extra inventory on hand to protect against variability in market demand or supply disruptions. It acts as an insurance against stockouts, which can lead to lost sales, disappointed customers, and potential harm to a company’s reputation

The theoretical underpinning for safety stock calculations often revolves around lead time, demand variability, and service level expectations. The classic safety stock formula is:

Safety Stock = (Max Lead Time – Average Lead Time) * Average Demand

Here, the Max Lead Time and Average Lead Time represent the longest and average time taken to replenish stock, and the Average Demand is the average units sold during that lead time.

Many companies modify this formula to consider the standard deviation of lead time and demand, as well as the desired service level (probability of not having a stockout).

Implementing safety stock requires a delicate balance. While having a high level of safety stock can prevent stockouts, it also increases inventory holding costs. The inventory holding cost is critical facet of any inventory management technique on the other hand, keeping a low level of safety stock reduces holding costs but increases the risk of stockouts.

A case study highlighting the effective use of safety stock is Amazon . The e-commerce giant uses advanced algorithms and machine learning techniques to determine optimal safety stock levels for millions of products. Amazon’s sophisticated inventory management system takes into account various factors, such as historical sales data, product life cycle, seasonal trends, and supplier reliability. This approach has reportedly helped Amazon maintain a high in-stock rate of 97.8% in 2020, reducing the risk of lost sales and improving customer satisfaction.

Moreover, a study by the International Journal of Production Economics found that a well-managed safety stock can lead to a 10-20% reduction in total inventory costs. This is achieved by maintaining a balance between holding costs and the cost of stockouts.

Despite its benefits, managing safety stock comes with challenges. It requires accurate data, sophisticated algorithms, and the ability to respond swiftly to changing market conditions. Businesses also need to periodically review and adjust their safety stock levels as demand patterns, lead times, and business goals change.

Batch Tracking

Batch tracking can mitigate the risks of product recalls. Batch tracking, also known as lot tracking, is a quality control inventory management technique that allows businesses to track goods along the distribution chain. It is especially important in industries where products need to be closely monitored for reasons of safety, compliance, or quality control, such as food, pharmaceuticals, and electronics.

In essence, batch tracking records the journey of a batch or lot of products or materials from their origin, through the manufacturing process, to the end consumer. This allows companies to manage recalls effectively, ensure regulatory compliance, and improve product quality.

The concept of batch tracking relies on the following principles:

Traceability

Every batch or lot of products should have a unique identifier that allows it to be tracked throughout the supply chain.

Transparency

Information about each batch, such as its origin, processing history, and distribution, should be recorded and readily available.

Accountability

Companies should take responsibility for the quality and safety of their products and have procedures in place for managing recalls or quality issues.

Case Studies

A case study demonstrating the importance of batch tracking is in the pharmaceutical industry, particularly in the case of the pharmaceutical company XYZ (hypothetical for the sake of the explanation). The company implemented batch tracking to improve its inventory management and product quality control. Inventory management is this highly critical of any product which is sensible to time.

The company assigned unique identifiers to each batch of drugs manufactured, enabling it to trace the journey of each batch from the raw materials used, through the manufacturing process, to the distribution to pharmacies. This allowed XYZ to quickly identify and isolate any batches that were associated with quality issues, reducing the scope and cost of recalls.

Furthermore, the implementation of batch tracking led to a decrease in carrying costs by about 27%, as the company was able to manage its inventory more effectively and reduce waste.

Additionally, a study by the Aberdeen Group found that companies using batch tracking had a 26% higher successful product completion rate compared to those not using batch tracking. This demonstrates how batch tracking can contribute to operational efficiency and product quality.

However, batch tracking can be challenging to implement. It requires sophisticated tracking systems, accurate data, and strong cooperation from all stakeholders in the supply chain. Therefore, businesses need to invest in the right technologies and processes to implement batch tracking effectively.

Vendor-Managed Inventory (VMI)

In a VMI arrangement, suppliers manage inventory levels. Vendor -Managed Inventory (VMI) is a supply chain practice where the supplier or vendor is responsible for maintaining the customer’s inventory levels. Under this model, the supplier has access to the customer’s inventory data and is responsible for generating purchase orders.

This practice aims to improve inventory turnover and reduce stockouts or overstock situations. Aligning the manufacturer’s production with the retailer’s sales cycle enhances the efficiency of the supply chain. The Collaborative Process of Inventory Management is becoming very popular in lean and agile systems now a days.

The VMI model is based on several principles:

Information Sharing

In a VMI relationship, the customer shares real-time data on stock levels, sales, and forecasts with the supplier. This transparency allows the supplier to better plan production and deliveries.

Inventory Ownership

The supplier retains ownership of the inventory until it’s sold, effectively transferring the risks associated with inventory management from the customer to the supplier.

Performance Metrics

The supplier’s performance is usually evaluated based on the level of customer service they provide, such as their ability to avoid stockouts and maintain optimal inventory levels.

A successful case study of VMI implementation comes from Barilla, an Italian pasta manufacturer. Before implementing VMI, Barilla suffered from significant demand variability, leading to stockouts and excess inventory. By adopting a VMI strategy, Barilla transferred the responsibility of inventory management to its suppliers.

With access to real-time sales data, suppliers were able to better forecast demand, optimize production schedules, and improve delivery performance. This resulted in a 30% reduction in stockout instances and a significant improvement in Barilla’s customer service levels.

The benefits of VMI are supported by numerous studies. According to research by the Journal of Operations Management, VMI can lead to an average inventory reduction of 31% and an increase in service levels by up to 6%.

However, implementing a VMI strategy requires a high degree of collaboration and trust between the customer and the supplier. Both parties need to invest in compatible IT systems, adopt standardized processes, and agree on performance metrics. The benefits of VMI also depend on the nature of the products, the stability of demand, and the capabilities of the supplier.

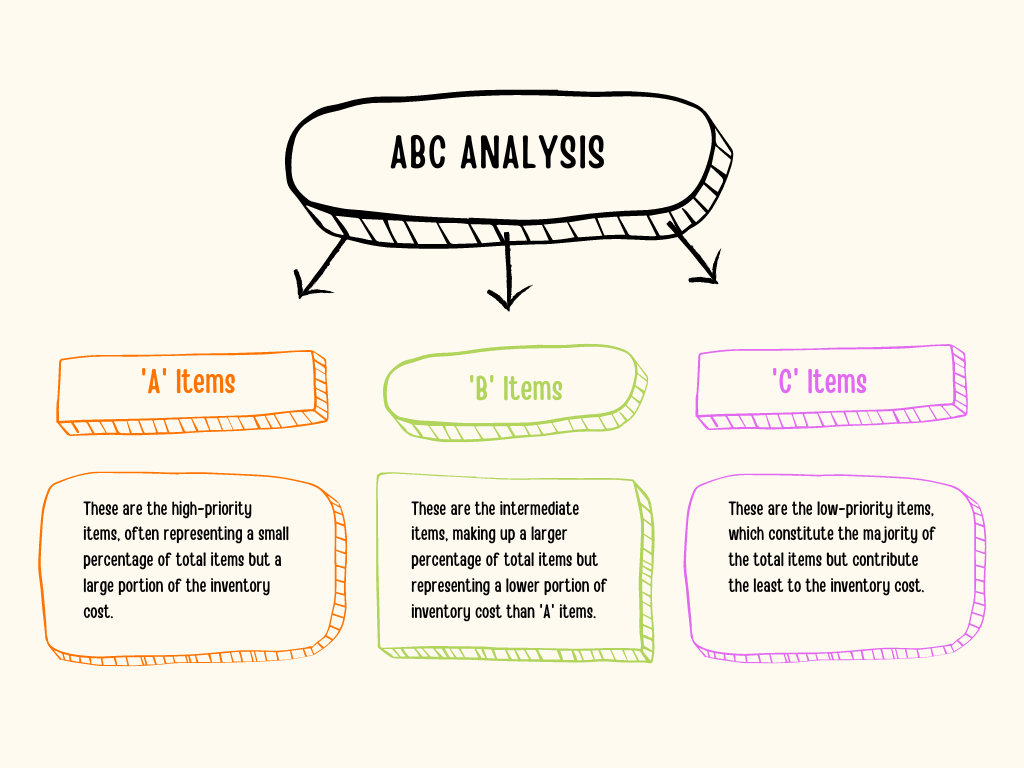

ABC Analysis

This involves categorizing inventory based on its importance and value. ABC analysis is a method of categorizing inventory into three categories based on their importance and value to the business. The system gets its name from the classes it involves: ‘A’ items are very important, ‘B’ items are important, and ‘C’ items are marginally important.

‘A’ Items: These are the high-priority items, often representing a small percentage of total items but a large portion of the inventory cost. They require close inventory control and rigorous demand forecasting.

‘B’ Items: These are the intermediate items, making up a larger percentage of total items but representing a lower portion of inventory cost than ‘A’ items. They require a moderate level of inventory control.

‘C’ Items: These are the low-priority items, which constitute the majority of the total items but contribute the least to the inventory cost. They require less stringent control and can be ordered in larger quantities less frequently.

The basic principle of ABC analysis is the Pareto principle, or the 80/20 rule, which suggests that 80% of the effects come from 20% of the causes. In the context of inventory management, it often happens that 80% of a company’s inventory value is made up of only 20% of its items. The categorization is a basic for any inventory management process

Example and Case Study

An example of the application of ABC analysis is in a pharmaceutical company, XYZ (hypothetical for the sake of the explanation). The company categorized its inventory based on the annual consumption value of each product (calculated as the annual demand multiplied by the cost per unit).

‘A’ items were the top 20% of items that accounted for about 70% of the company’s total inventory value. ‘B’ items were the next 30% of items, contributing around 25% of the total inventory value. The remaining 50% of items, classified as ‘C’ items, contributed only 5% to the inventory value.

By focusing its inventory management efforts on ‘A’ items, XYZ was able to manage its inventory more effectively, leading to a decrease in carrying costs by about 27%.

Several studies have validated the benefits of ABC analysis. For instance, a study published in the Journal of Operations Management found that companies using ABC analysis achieved a 14% reduction in inventory costs compared to those not using it.

However, implementing ABC analysis requires a good understanding of the company’s products and market dynamics. It also requires the collection and analysis of accurate demand and cost data. Therefore, companies need to invest in data management and analytical capabilities to apply ABC analysis effectively.

Inventory Turnover Ratio

This measures how often inventory is sold and replaced within a specific period.

The inventory turnover ratio is a key performance indicator that measures the efficiency of inventory management. It represents how many times a company has sold and replaced its inventory during a specific period, usually a year. The ratio provides insights into a company’s operational efficiency, liquidity, and overall financial health.

The formula to calculate the inventory turnover ratio is:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Cost of Goods Sold (COGS) is the total cost of all goods sold during a specific time period.

Average Inventory is the mean value of inventory during the same time period, usually calculated as the average of the inventory levels at the start and end of the period.

A higher inventory turnover ratio indicates that a company sells its inventory quickly, implying efficient inventory management and high demand for its products. Conversely, a lower ratio could suggest overstocking, slow sales, or obsolete inventory.

Consider a hypothetical example: a retail company, XYZ, which had a COGS of $2 million and an average inventory of $500,000 for the year. By applying the formula, XYZ’s inventory turnover ratio would be 4. This means that XYZ sold and replaced its inventory four times during the year.

The optimal inventory turnover ratio can vary significantly across different industries. For instance, in fast-moving industries like fashion or perishable goods, a high turnover ratio is desirable. In contrast, industries with slower-moving goods, like furniture or appliances, may have a lower turnover ratio. Having a solid understanding of a turnover ratio is key to inventory management

According to a study published in the Journal of Business Logistics, companies with higher inventory turnover ratios tend to have higher profit margins. The research found that a 10% increase in the inventory turnover ratio could lead to a 1% increase in the profit margin.

However, interpreting the inventory turnover ratio requires caution. While a high turnover ratio can suggest efficiency, it might also indicate inadequate inventory levels, leading to stockouts and lost sales. On the other hand, a low turnover ratio could signal overstocking or weak sales, but it might also reflect a strategic decision to maintain higher inventory levels to guard against supply chain disruptions.

Just-in-Time (JIT) Inventory

This method reduces inventory carrying costs. Just-in-Time (JIT) inventory management is a strategy aimed at reducing in-process inventory and its associated carrying costs. The approach is based on producing goods to meet demand precisely when needed in the production process, not before, thereby minimizing inventory levels.

The underlying principles of JIT are:

Pull System

Production is driven by customer demand rather than forecasts. Each stage of the production process only produces what the next stage needs, and the process starts when the final customer places an order.

Zero Inventory

The aim is to eliminate inventory, both raw materials and finished goods, as much as possible. Inventory is seen as a sign of inefficiency, indicating overproduction and waste.

Continuous Improvement (Kaizen)

JIT is closely associated with the principle of Kaizen, which focuses on continuous improvement in all aspects of the business, including reducing waste, improving efficiency, and enhancing quality.

Toyota is famously known for implementing JIT in its production system, known as the Toyota Production System. Before JIT, Toyota, like many other companies, produced more than necessary and stored surplus goods in warehouses, leading to high inventory costs and waste.

Implementing JIT allowed Toyota to dramatically reduce its raw material, work-in-process, and finished goods inventories. By synchronizing the production rate with consumer demand, Toyota reduced its inventory levels by more than 50%, leading to significant cost savings. It also led to an improvement in quality, as it was easier to detect defects in a system with minimal inventory.

Several studies have demonstrated the benefits of JIT. For instance, a study published in the Journal of Operations Management found that implementing JIT can lead to an improvement in return on assets (ROA) by up to 70%.

However, successful implementation of JIT requires a stable and reliable supply chain, efficient production processes, and accurate demand forecasting. Any disruption in the supply chain, such as supplier failure or transportation delays, can halt production and lead to stockouts. Thus, while JIT can bring significant cost savings and efficiency improvements, it also comes with its own set of risks.

Real-time Tracking

This involves monitoring inventory in real-time. Real-time tracking in inventory management refers to the continuous and instantaneous tracking of inventory items, from the moment they enter the warehouse until they are sold and dispatched. It involves the use of advanced technologies, such as RFID tags, barcodes, IoT devices, and cloud-based software, to monitor and update inventory levels in real-time. With advanced data analytics, real-time inventory management is becoming more economical.

The primary principles of real-time tracking are:

Instantaneous Updates

Every movement of inventory, from receiving and storing to picking and shipping, is immediately recorded and reflected in the inventory levels.

Real-time tracking provides a clear and accurate view of the current inventory levels, location of items, and status of orders at any given time.

By eliminating manual entry and the delay in updating inventory records, real-time tracking significantly improves the accuracy of inventory data.

A case in point is Amazon, which uses real-time tracking extensively in its fulfillment centers. Amazon utilizes RFID tags, automated guided vehicles (AGVs), and sophisticated inventory management systems to track each item in its vast warehouses in real time. This allows Amazon to maintain accurate inventory records, streamline order fulfillment, and provide real-time updates to customers.

Implementing real-time tracking resulted in a significant reduction in order fulfillment time, an increase in warehouse efficiency, and improved customer satisfaction due to the visibility into order status. In terms of numbers, Amazon was reportedly able to reduce its “click to ship” time, that is, the time from when a customer places an order to when it’s shipped, from 60-75 minutes to under 15 minutes.

Several studies have shown the benefits of real-time tracking. According to a report by Zebra Technologies, businesses that implemented real-time tracking reported an average improvement of 32% in inventory accuracy and a 27% acceleration in order cycle times.

However, implementing real-time tracking requires a significant investment in technology and the development of standardized processes. It also involves a shift in mindset from periodic to continuous inventory management. Therefore, businesses need to carefully assess their needs, capabilities, and resources before implementing real-time tracking.

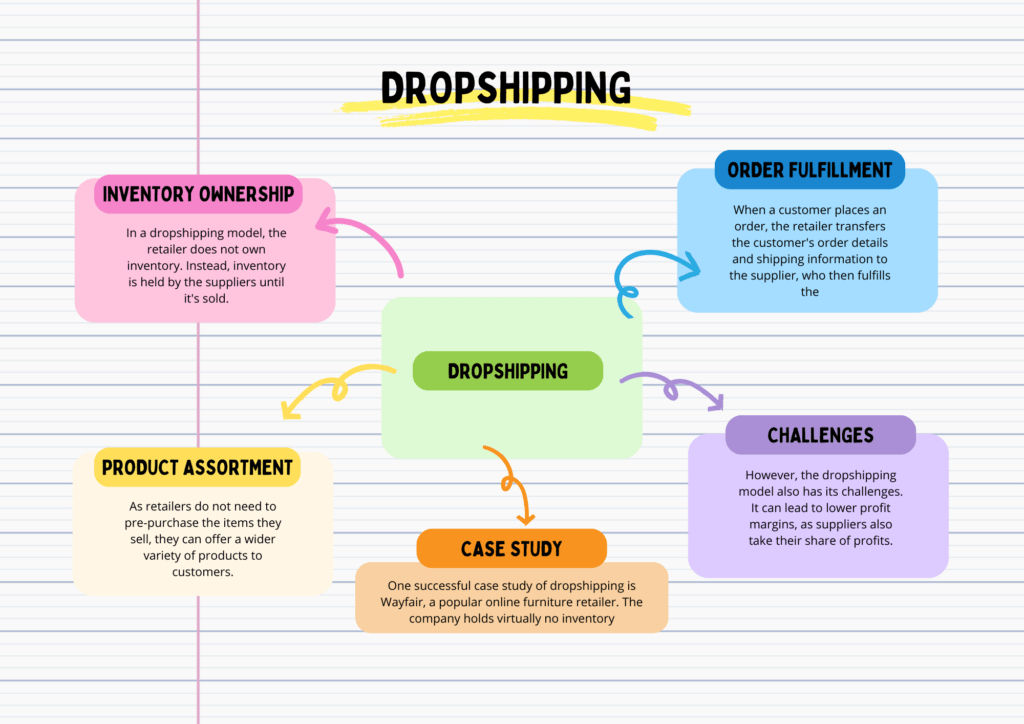

Dropshipping

This involves selling products without stocking them. Dropshipping is a retail fulfillment model in which the retailer does not keep goods in stock. Instead, when a retailer sells a product using the dropshipping model, it purchases the item from a third party—usually a wholesaler or manufacturer—and has it shipped directly to the customer. This eliminates the need for the retailer to handle the product directly, reducing inventory and warehousing requirements. Inventory management with dropshipping needs heavy optimization though.

The fundamental principles of dropshipping are:

In a dropshipping model, the retailer does not own inventory. Instead, inventory is held by the suppliers until it’s sold.

Order Fulfillment

When a customer places an order, the retailer transfers the customer’s order details and shipping information to the supplier, who then fulfills the order directly to the customer.

Product Assortment

As retailers do not need to pre-purchase the items they sell, they can offer a wider variety of products to customers.

One successful case study of dropshipping is Wayfair, a popular online furniture retailer. The company holds virtually no inventory and relies extensively on dropshipping. When a customer places an order on Wayfair’s platform, the order is sent to the manufacturer, who ships the item directly to the customer. This model allows Wayfair to offer a vast selection of products without the need to manage complex inventory or large warehouses.

According to data from a report by Market Research Future, the global dropshipping market size was projected to reach approximately $557.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 28.8% from 2018.

However, the dropshipping model also has its challenges. It can lead to lower profit margins, as suppliers also take their share of profits. Also, because retailers don’t control the entire supply chain, they can face difficulties with product quality control, order fulfillment, and customer service.

Cross-docking

This involves transferring incoming shipments directly to outgoing trucks, reducing warehouse storage needs.

Cross-docking is a logistics strategy in which products from a supplier or manufacturing plant are distributed directly to customers with minimal to no handling or storage time. The term “cross-docking” comes from the process of receiving products through an inbound dock and then transferring them across the dock to the outbound transportation dock. Cross docking is becoming more popular for large organizations with decentralized inventory management

The core principles of cross-docking include:

In cross-docking, speed is key. The objective is to unload materials from an incoming semi-trailer truck or rail car and then directly load these materials onto outbound trucks or trailers with little to no storage in between.

Synchronization

The success of cross-docking depends on the synchronization of inbound and outbound transport. The goal is to ensure that the incoming goods arrive just in time to be loaded onto the outbound transport.

Cross-docking requires a central site where the routing of products is handled. At this site, products are received from multiple sources and then sorted onto outbound trucks going to different destinations.

An effective example of cross-docking is Walmart’s distribution model. Walmart’s suppliers send full truckloads of products to a Walmart distribution center, where they’re then distributed to individual stores in less-than-truckload (LTL) quantities. Walmart uses cross-docking efficiently to get products from suppliers to their stores without holding inventory at the distribution centers. It helps them to reduce inventory holding costs, minimize storage requirements, and get products into stores faster, which is crucial in retail industries.

According to a study published in the International Journal of Retail & Distribution Management, the implementation of cross-docking can lead to a reduction in order cycle time by 33%, and inventory reduction by up to 50%.

However, to successfully implement cross-docking, companies require significant planning, investment in a central routing facility, and sophisticated logistics software to coordinate and synchronize transport schedules. It’s also crucial to have reliable suppliers that can adhere to strict delivery schedules. If these conditions aren’t met, cross-docking can lead to increased transportation costs, delivery delays, and customer dissatisfaction.

Inventory Management Software

Companies like Oracle, SAP, and Microsoft offer advanced inventory management software that can automate various processes, resulting in reduced errors and increased efficiency.

Inventory management software is a tool that helps businesses track and manage their inventory levels, sales, orders, and deliveries. It can also be used to create purchase orders, back orders, and invoices. The software’s primary purpose is to avoid product overstock and outages, ensuring that the right amount of stock is maintained at all times. Using these software are essential for building a strong inventory management system

The key features of inventory management software include:

Inventory Tracking

This feature allows businesses to track their inventory levels in real time. The software can provide updates when stock is low or when it’s time to reorder.

Barcode Scanning

Many inventory management systems come with barcode scanning capabilities. This allows businesses to quickly input and track products, reducing manual errors.

Reporting and Analytics

These features provide businesses with insights into their inventory levels, sales trends, and order history. This can help businesses make more informed decisions about stock management, pricing, and sales strategies.

Integration Capabilities: Inventory management software can often be integrated with other business systems, such as accounting software, e-commerce platforms, and CRM systems, to streamline operations.

One example of a company leveraging inventory management software is Zara, the Spanish clothing retailer. Zara uses sophisticated inventory management software to track each item in real-time, from when it’s manufactured to when it’s sold. This allows Zara to keep track of its fast-moving inventory, respond quickly to changes in demand, and minimize stockouts and overstock.

According to a report by Mordor Intelligence, the global inventory management software market was valued at USD 2.42 billion in 2020 and is expected to reach USD 5.6 billion by 2026, growing at a CAGR of 15% during the forecast period (2021-2026).

However, implementing inventory management software requires a significant investment in technology and may require staff training. It also requires the collection and analysis of accurate data. Therefore, businesses need to carefully evaluate their needs and resources before deciding to invest in inventory management software.

Consignment Inventory

Here, payment to suppliers is made only when their goods are sold.

Consignment inventory is a business model in which a consignee (retailer) agrees to receive and store products from a consignor (supplier or manufacturer), but the consignor retains ownership of the products until they are sold. Once the product is sold, the consignee pays the consignor for the inventory. It is very similar yet different from dropshipping model of inventory management.

The core principles of consignment inventory include:

In a consignment inventory agreement, the consignor retains the ownership of the goods until they are sold. This implies that the consignor bears the financial risk of the inventory until the point of sale.

The consignee pays for the inventory only after it is sold to the end consumer. The unsold inventory can be returned to the consignor, reducing the financial risk for the consignee.

Inventory Management

Typically, the consignor is responsible for managing the inventory, which includes replenishing stock when levels are low and removing outdated or unsold merchandise.

A great example of the consignment model is the relationship between book authors (consignors) and bookstores (consignees). Many bookstores will display books, particularly from unknown or independent authors, on a consignment basis. This allows the bookstore to offer a wide range of titles without the risk of investing in inventory that may not sell.

According to data from Stitch Labs, using a consignment model can increase revenue by consignment model can increase revenue by as much as 20%, as retailers can offer a wider variety of products without the risk of unsold inventory.

However, there are potential downsides to the consignment model. For consignors, delayed revenue recognition and the risk of not selling the inventory can be significant. For consignees, consignment inventory can take up valuable retail space without providing immediate revenue. Also, managing consignment inventory can be complex, requiring careful tracking and accounting to ensure accurate payment upon sale.

Cycle Counting

This involves regularly counting a subset of inventory.

Cycle counting is an inventory auditing technique where a small subset of inventory, in a specific location, is counted on a specified day. It is a method used by businesses to count their inventory continuously and cyclically throughout the year, rather than counting all inventory at once during a full physical inventory count. Cycle counts contrast with traditional physical inventory counts, where operations are halted once or twice a year to count all inventory items. To bring discipline into inventory management this process is necessary.

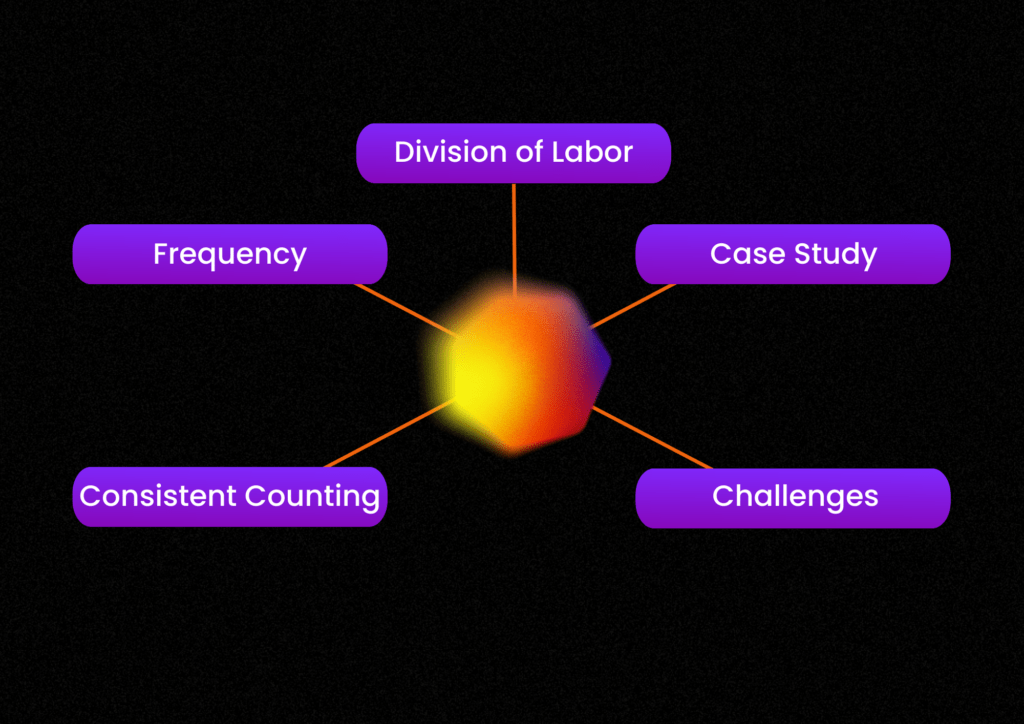

The essential principles of cycle counting are:

Consistent Counting

In a cycle counting system, a small, specific subset of inventory is counted at regular intervals, ensuring ongoing accuracy.

Inventory items are not all counted at the same frequency. High-value items, fast-moving items, or items critical to business operations are often counted more frequently.

Division of Labor

By breaking down the task of inventory counting into smaller parts, the job can be completed without disrupting normal operations.

A successful implementation of cycle counting can be found at Apple Inc. Apple uses cycle counting to maintain an accurate inventory record. This technique helps them to identify and correct potential problems early, reducing discrepancies between actual and recorded inventory.

A study by the Association for Supply Chain Management (APICS) found that companies using cycle counting systems could achieve inventory accuracy levels of 97% or higher. This contrasts with a traditional annual physical inventory system, which often results in lower overall accuracy due to a lack of frequent validation.

While cycle counting can significantly improve inventory accuracy, its implementation is not without challenges. It requires a consistent and ongoing effort and requires businesses to invest in proper training for staff to conduct the counts effectively and efficiently. If not appropriately managed, cycle counting can lead to discrepancies and errors.

Inventory Shrinkage Control

Implementing measures to control shrinkage can reduce inventory losses. Inventory management thus takes central stage.

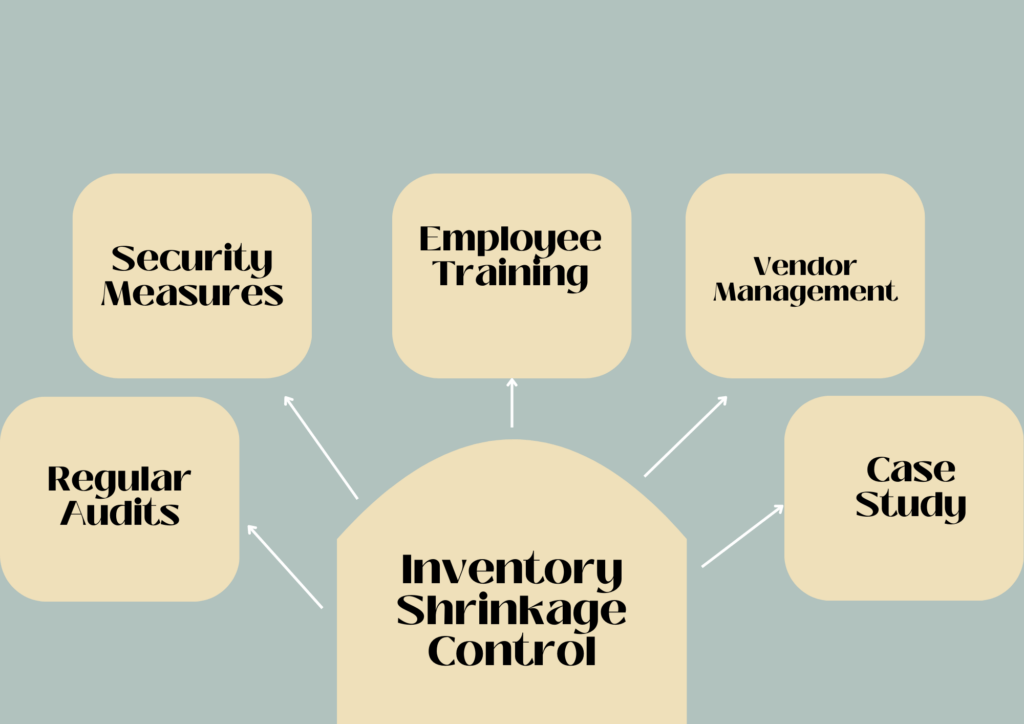

Inventory shrinkage refers to the loss of products between the point of manufacture or purchase from suppliers and the point of sale. It is a significant issue that can impact a company’s bottom line. The main causes of inventory shrinkage include theft, damages, miscounting, and supplier fraud. Instilling discipline is required for any type of inventory management.

Here are the key principles to control inventory shrinkage:

Regular Audits

Regular inventory audits, including cycle counting, can help identify shrinkage early and mitigate its impact. It allows you to identify discrepancies between your physical inventory and your inventory records, indicating potential shrinkage.

Security Measures

Implementing security measures, such as surveillance cameras, electronic article surveillance (EAS) systems, and security personnel, can deter theft, one of the significant contributors to inventory shrinkage.

Employee Training

Well-trained employees are more likely to handle inventory properly, reducing losses due to damage or miscounting. Also, educating them about the consequences of theft, including job loss and legal action, can deter internal theft.

Vendor Management

Establishing strong relationships with vendors and carefully monitoring their activities can help prevent supplier fraud. This can include checking shipments for accuracy and quality.

One successful case study of shrinkage control is at Target Corporation. The company employs advanced analytics to identify patterns in theft and uses electronic surveillance systems throughout their stores. They also have a rigorous vendor vetting process to prevent vendor fraud. These measures have reportedly resulted in a substantial reduction in inventory shrinkage.

According to the National Retail Federation’s 2020 National Retail Security Survey, the average inventory shrink rate in the U.S. retail industry is around 1.62% of sales. This may seem like a small percentage, but given the volume of sales in the retail industry, it can amount to billions of dollars.

Centralized Inventory

Centralizing inventory can reduce costs and improve efficiency.

A centralized inventory management system is a method where a company maintains its entire inventory from one central location or few select locations. Rather than keeping stock in various places such as individual stores or warehouses scattered across different regions, all products are kept in one central warehouse from which they’re distributed to individual sale locations or directly to consumers. Organizations are looking forward to centralized inventory management after Covid disruptions.

The core principles of centralized inventory management include:

Central Location

In centralized inventory management, all inventory is managed from one central location. This could be a central warehouse, distribution center, or a fulfillment center.

Streamlined Supply Chain

Centralizing inventory allows for a more streamlined supply chain as all goods come in and go out of the same place. This can make it easier to manage and keep track of inventory.

Consolidated Management

With centralized inventory, inventory management is consolidated. This means that one team (or sometimes one person) can oversee the entire inventory, which can lead to more effective management and decision-making.

One notable example of successful centralized inventory management is Amazon. Amazon keeps its inventory in large, strategically located fulfillment centers from where they dispatch products directly to customers. This centralized system allows Amazon to manage and control its inventory effectively and deliver products rapidly.

According to a report from Accenture, centralizing inventory management can lead to a 10% – 20% reduction in inventory carrying costs. It also can help companies enhance customer service and increase sales by ensuring the right products are available at the right time.

However, there are potential drawbacks to centralized inventory management. One of the main risks is that if the central warehouse encounters a problem (like a natural disaster or a major system failure), it can disrupt the entire supply chain. Also, centralized inventory may not always provide the speed needed for rapid delivery to distant locations.

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page

Inventory Management Software: A Case Study

- Post author: Maryliya M J

- Post published: January 16, 2024

- Reading time: 13 mins read

Table of Contents

Inventory management plays a crucial role in the success of businesses across industries . Efficiently managing inventory ensures that the right products are available at the right time, minimizing stockouts and carrying costs. To streamline this process and enhance operational efficiency, businesses are increasingly turning to inventory management software solutions.

Introduction to Inventory Management Software

What is inventory management software.

Inventory management software is a powerful tool that helps businesses track, control, and optimize their inventory. It provides real-time visibility into stock levels, automates essential tasks like reordering and restocking, and enables businesses to make data-driven decisions to prevent stockouts or overstocking.

Importance of Inventory Management in Business Operations

Effective inventory management is crucial for businesses of all sizes. It ensures that the right products are available at the right time, minimizes storage costs, prevents stock obsolescence, and enhances customer satisfaction. By streamlining inventory processes and improving accuracy, businesses can reduce the risk of errors, increase operational efficiency, and ultimately boost profitability.

The Need for Efficient Inventory Management

Common inventory management challenges.

Managing inventory can be a complex and challenging task. Some common challenges businesses face include inaccurate demand forecasting, manual tracking leading to errors, inefficient order fulfillment, poor visibility of stock levels, and difficulties in identifying slow-moving or obsolete items.

Impact of Inefficient Inventory Management

Inefficient inventory management can have far-reaching consequences for a business. It can result in stockouts, leading to lost sales and dissatisfied customers. Conversely, overstocking ties up capital, increases storage costs, and risks product obsolescence. In addition, inefficient inventory management can lead to inaccuracies in financial reporting, hinder supply chain efficiency, and hamper overall business growth.

About the Client

Our client, a retail chain, faced challenges in tracking inventory levels across multiple stores. With a growing inventory and diverse product lines, they sought to enhance their stock control, automate reorder processes, and optimize inventory turnover. Recognizing the need for a robust solution, they engaged in the development of a tailored Inventory Management Software ( IMS ).

Project Overview

The project aimed to develop a comprehensive .NET-based IMS to address the client’s challenges. The primary objectives included automating stock control, integrating with point-of-sale (POS) systems, providing real-time stock visibility, and incorporating predictive analytics for effective inventory planning and ordering.

The Challenges

- Manual Inventory Tracking: The existing manual processes for inventory tracking led to inaccuracies and inefficiencies.

- Lack of Real-time Visibility: Limited visibility into stock levels across multiple stores resulted in delays and stockouts.

- Inefficient Reorder Processes: Manual reorder processes were time-consuming and prone to errors.

The Solution

Our team of skilled developers and project managers collaborated to design and implement a comprehensive .NET-based Inventory Management Software. The solution included modules for automated stock control, integration with POS systems, real-time stock visibility, and predictive analytics for optimized inventory planning and ordering.

Key Features of the IMS

- Automated Stock Control: The IMS automated stock control processes, ensuring accurate and real-time tracking of inventory levels.

- POS Integration: Seamless integration with point-of-sale systems provided synchronized data, enhancing overall efficiency.

- Real-time Stock Visibility: The software offered real-time visibility into stock levels across multiple stores, reducing delays and stockouts.

- Predictive Analytics: Advanced analytics tools provided insights into inventory trends, facilitating proactive planning and ordering.

The Outcome

The Inventory Management Software was successfully deployed, resulting in significant improvements in stock control and inventory management. Automated processes, POS integration, and predictive analytics contributed to a more streamlined and optimized inventory turnover.

Conclusion: The Future of IMS

Our team’s expertise in developing a tailored Inventory Management Software using .NET technologies effectively addressed the client’s challenges. The implementation of automated stock control, POS integration, and predictive analytics tools contributed to a more efficient and responsive inventory management system.

In conclusion, inventory management software has proven to be a valuable tool for businesses seeking to optimize their inventory management processes. Through the case study analysis and exploration of key features and benefits, it is evident that implementing such software can lead to improved efficiency, cost reduction, and better decision-making. While challenges may arise during implementation, adopting best practices and staying proactive can ensure a successful integration. As technology continues to advance, the future of inventory management software holds great promise, with advancements such as AI and predictive analytics poised to revolutionize how businesses manage their inventory. By embracing these innovations and staying ahead of the curve, businesses can unlock new levels of productivity and success in their operations.

Are you struggling with inventory tracking and management challenges? Contact us today to explore how our expertise in IMS development can transform your inventory processes and drive efficiency.

What is inventory management software?

Inventory management software is a technology solution designed to track, organize, and manage a company’s inventory levels, orders, and stock movements. It provides businesses with real-time visibility into their inventory, helping them streamline operations, reduce costs, and improve customer satisfaction.

What are the benefits of using inventory management software?

Inventory management software offers several benefits, including improved inventory accuracy, reduced stockouts and overstocking, enhanced order fulfillment, increased operational efficiency, better forecasting, optimized purchasing decisions, and improved customer service. It also helps automate manual tasks, centralize data, and provide actionable insights for informed decision-making.

What challenges can occur during the implementation of inventory management software?

Implementing inventory management software can come with challenges such as data migration and integration, staff training and adaptation, resistance to change, customization requirements, and potential disruptions to ongoing business operations. However, with proper planning, communication, and support, these challenges can be overcome, leading to a successful implementation.

How does inventory management software contribute to the future of inventory management?

Inventory management software is constantly evolving to meet the changing needs of businesses. The future of inventory management software lies in advancements such as artificial intelligence (AI), machine learning , internet of things ( IoT ), and predictive analytics. These technologies will enable businesses to automate processes, optimize inventory levels, improve demand forecasting accuracy, and gain valuable insights for strategic decision-making, ultimately driving efficiency and profitability.

You Might Also Like

Employee Training Management Software: A Case Study

Supply Chain Management Software: A Case Study

Telemedicine Platform for Remote Patient Care: A Case Study

Book a free consultation.

Tailored Solutions, Expert Advice, and Project Estimates Await.

Expect a Prompt Call from one of our Account Managers.

- Elite IT Professionals

- Time Zone Aligned

- Experienced Team

At Zenkins, we bring together a curated network of elite IT professionals ready to elevate your projects to new heights. From seasoned developers to innovative designers, our handpicked talent pool is here to turn your visions into reality. Experience unparalleled expertise, reliability, and dedication to excellence with our team of Elite IT Professionals.

At Zenkins, we understand the importance of global collaboration. That’s why our team is strategically aligned across time zones, ensuring seamless communication and productivity no matter where you are. From brainstorming sessions to project updates, our time zone-aligned approach guarantees that deadlines are met and progress never stalls. Experience the convenience of working with a team that’s always in sync.

At Zenkins, we pride ourselves on our experienced team of professionals who bring years of industry knowledge and skill to every project. From seasoned developers to seasoned project managers, our team has the expertise to tackle even the most complex challenges. With a proven track record of success, we deliver results that exceed expectations.

+91 70690 18504

[email protected]

Zenkins is a leading software development company based in India, specializing in SAAS Product Development, Digital Transformation, and Product Engineering. With a dedicated team of professionals and a commitment to excellence, we deliver innovative solutions that drive business growth and success. Partner with Zenkins for all your software development needs and experience the difference firsthand.

- Methodologies

- Technologies

- Our Services

- IT Staffing Services

- Software Outsourcing

- .NET Development Company

- Software Product Development Company

- Careers @Zenkins

- Current Openings

- Case Studies

- Technology Insights

- Careers Insights

Privacy Overview

IMAGES

COMMENTS

How Poor Inventory Management Can Kill a Brand. When supply chain and inventory problems arise, retailers face some consequences. Here are some poor inventory management examples: 1) Using outdated methods to track items, such as: Manual inventory tracking, which becomes time-consuming and error-prone as your company grows. You'll always be ...